The oil feed banjo bolts are a known oil leakage problem. The banjo bolts use copper washers to seal their connections. Over time these washers become hardened and brittle. Once they start to leak they must be replaced.

I had to remove the valve covers to address the valve cover half-moon seal problem, (covered in another link on this website). This gave me a somewhat better access to the banjo bolts located at the rear of the tappet blocks. Although they were not leaking, my advice is, if you have access, change those bad boys. With everything in place on the engine, it's a bitch. The replacement tappet block banjo bolts and washers are manufactured by Ron Kelnhofer. While the basic design is the same, Ron's bolts are slightly longer to compensate for the thicker copper washers. The washers are annealed to aid in sealing.

The project starts by removing the oil feed banjo bolt at the oil filter location. (red arrow photograph below) For clarity, the oil filter has been removed. Copper pipe is my engine breather vent. (Note that the engine breather pipe has been reworked as per the PCV link on this website).

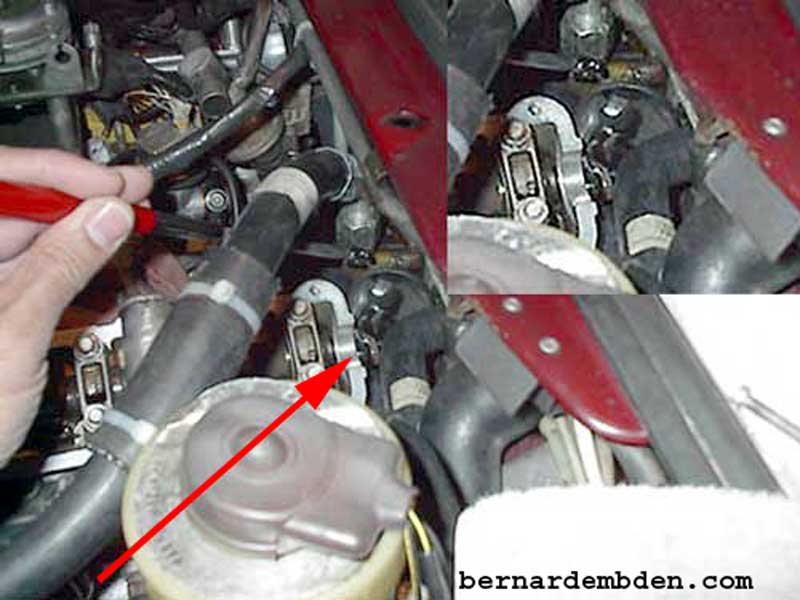

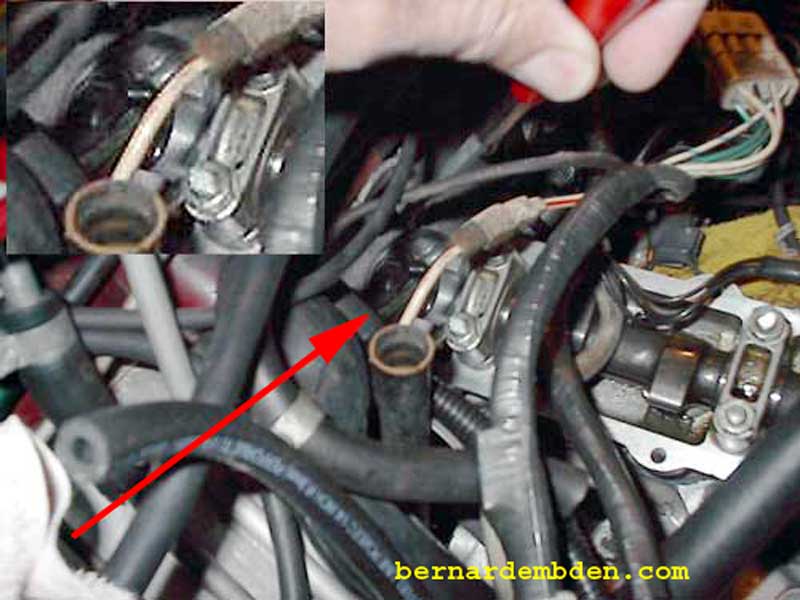

Next are the banjo fittings at the rear of the tappet blocks. These are a real PIA. On the left side there is approx. 3 inches of clearance to work with. There have been many suggestions as to the methodology involved in getting the second copper washer on. (this second washer installs between the banjo fitting and the tappet block.) Most suggestions recommend using a piece of thread to hold the washer while you install the bolt. I use a small diameter wire. I don't recommend thread, as the thread might break or unravel and leave some material between the washer and tappet block. Pictured below is a multi-strand fine diameter wire used to hold the second washer in place and (green arrow second photograph below) using the wire to position the washer as the banjo bolt is installed.

Tighten the bolt by hand.

Use a mirror if necessary to make sure both washers are installed correctly before final tightening.

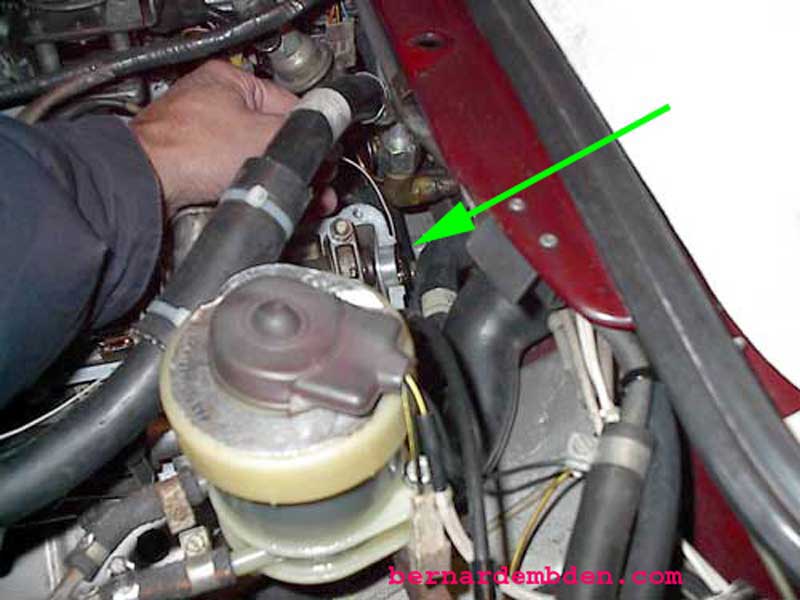

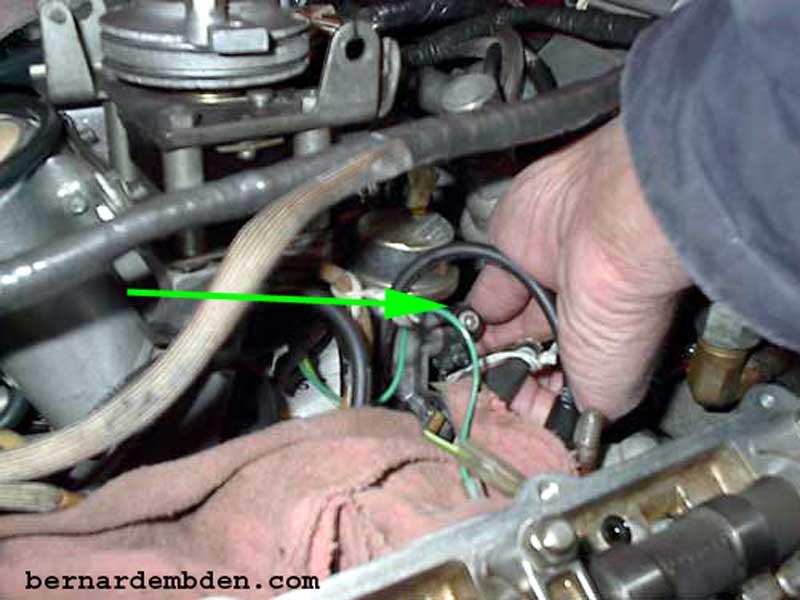

I recommend changing all the oil feed banjo washers. Access to the washers at the base of the throttle pedestal is limited, (green arrow photograph below) but significantly better with the valve covers off.

The right side of the tappet block will test your patience. Clearance is almost zero. I strongly recommend that you purchase an extra washer and bolt. Few things are as certain as this. You will drop a washer or bolt into the dark recess of the engine compartment before the project is completed. You will not find them. You will say bad words.

Again, make sure both washers are in place before you tighten the banjo bolt. Use a mirror. (red arrow photograph below) These washers are almost impossible to see due to their location.

Project completed. Start engine and check for leakage.