Varying the throttle opening varies the pressure within the plenum chamber. This varying plenum pressure is used to provide input to the ECU to control the duration on the injector opening pulse. The Manifold Pressure Sensor, fitted with a separate diaphragm system that compensates for ambient barometric variances, is responsible for sensing the pressure within the plenum.

The Manifold Pressure Sensor can be adjusted.

Adjustment is not necessary, nor recommended, under normal conditions. However if all other means fail to get the emissions or idle quality within factory specifications then adjusting the manifold sensor becomes an option.

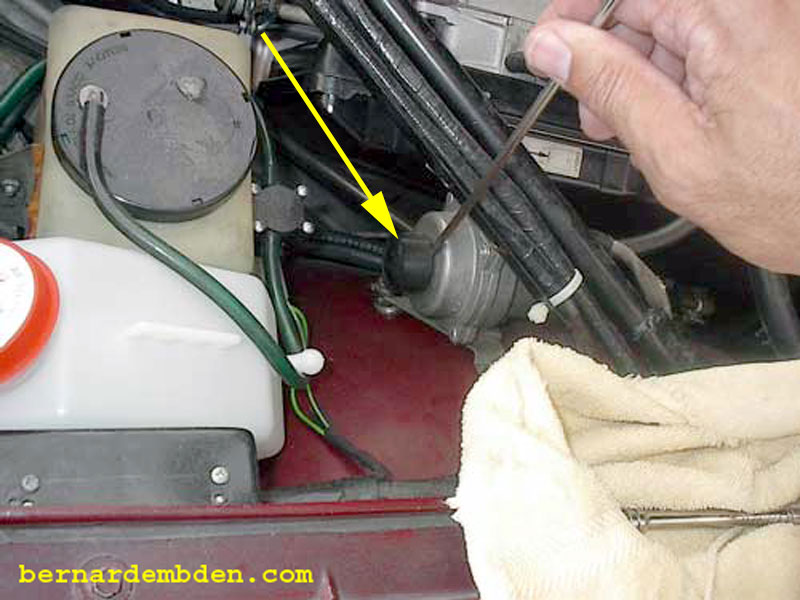

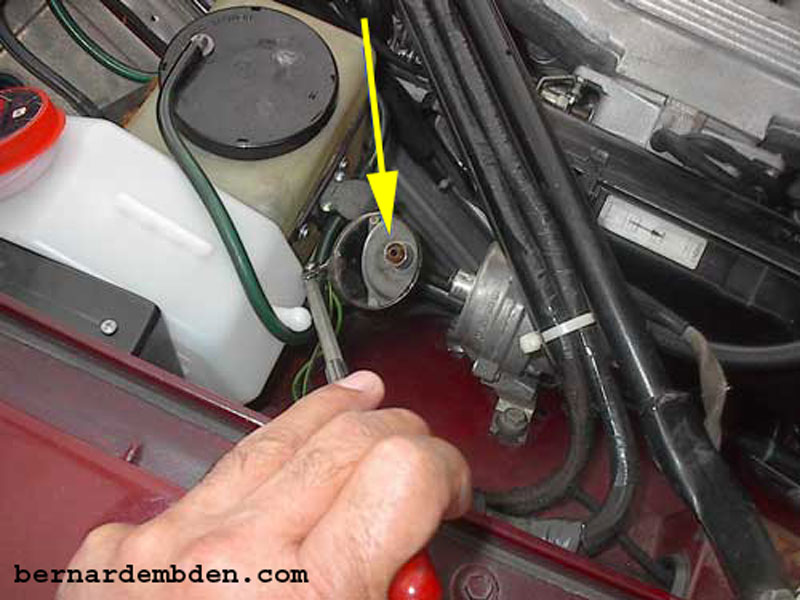

First, gently pry and remove the protective plastic cap the covers the adjustment screw. (yellow arrow photograph below).

The "Allen wrench" adjustment screw is clearly visible (green arrow photograph below). Note that I have relocated the Manifold Adjustment Sensor on my car to make room for my cold air intake modification. Radiator recovery canister project is also visible. Both projects are covered else ware in this website.

A mechanic's mirror provides a closer look at the adjustment screw. (yellow arrow photograph below).

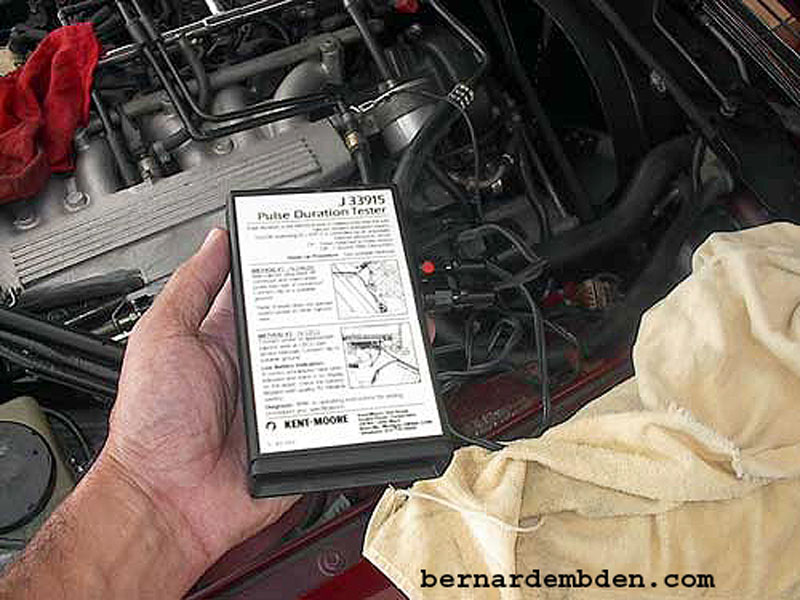

In order to adjust the sensor, a meter of some type is needed. Anything that measures exhaust emissions or injector pulse width is adequate. I use a J33915 Pulse Duration Tester manufactured by Kent Moore instruments. The tester is connected to the injector wiring at the harness.

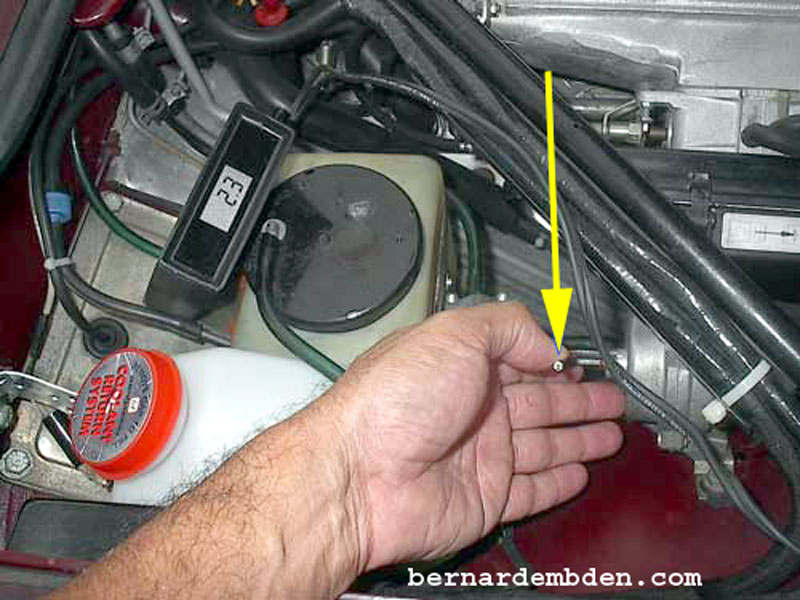

Place the appropriate size Allen wrench (5/32) in the sensor adjustment screw.

Located the Pulse Duration Tester where it is clearly visible. Note initial reading on the tester. When the engine is cold, a longer injector pulse width is normal. The meter reading of 3.6 indicates the duration of the injector pulse. The longer the pulse, the longer the injector stays open and the more fuel is introduced into the intake manifold.

As the engine warms up, the pulse width becomes shorter. For my car, a pulse width of 2.5 is within the acceptable range when the engine is hot.

Turning the Allen wrench clockwise (yellow arrow photograph below) decreases the pulse width. This effectively reduces fuel to the engine.

A pulse width of 2.2 or less will usually adversely affect idle quality. Once the adjustment is satisfactory, replace the protective plastic cap.