The fuel cooler on the Jaguar V-12 engine is insulated with an asbestos type material that invariably becomes dull and faded. This looked incongruous in my otherwise clean engine compartment.

I decided to fix this problem area by covering the fuel cooler with a chromed exterior.

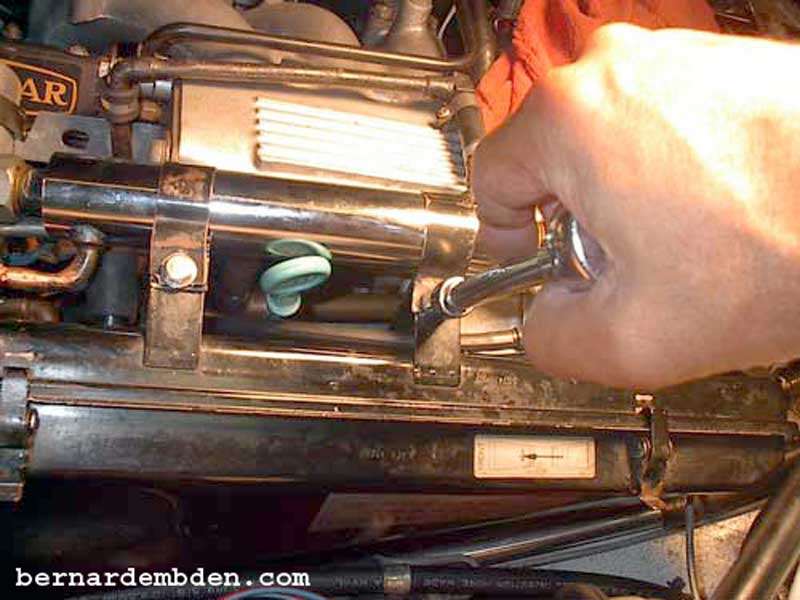

To start the project, I removed the fuel cooler brackets. The fuel lines must also be removed to gain access to the fuel cooler insulators. The fuel system should always be de-pressurized before working on it.

Insulator jacket is removed in two halves from the cooler and fuel line entry and exit nipples.

I purchased a chromed copper sink drainpipe at Home Depot. The pipe must be 1 1/2 inch in diameter at least 8 inches long. Cost $3.00 US

The objective is to cut the pipe exactly down the center, creating two identical halves. Use a straight edge to mark a straight line. Masking tape allows me to see my marks.

I used a hacksaw for the initial cuts

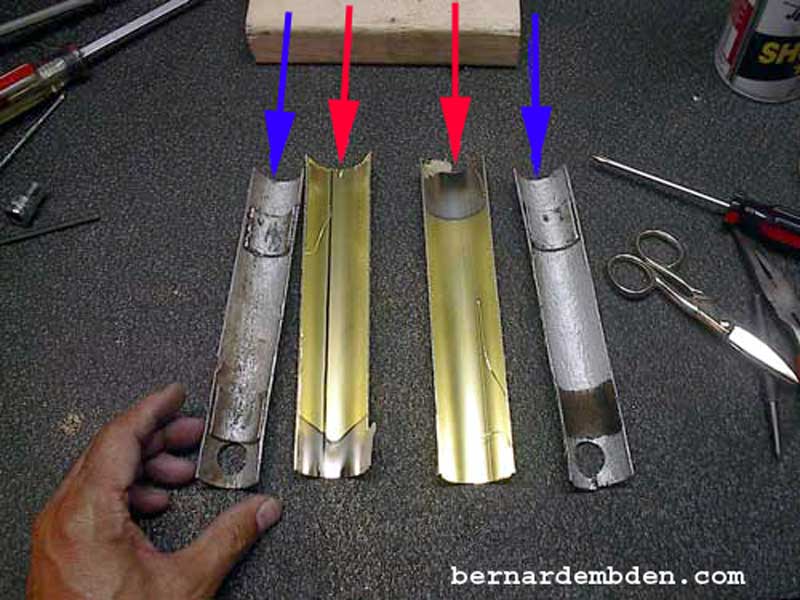

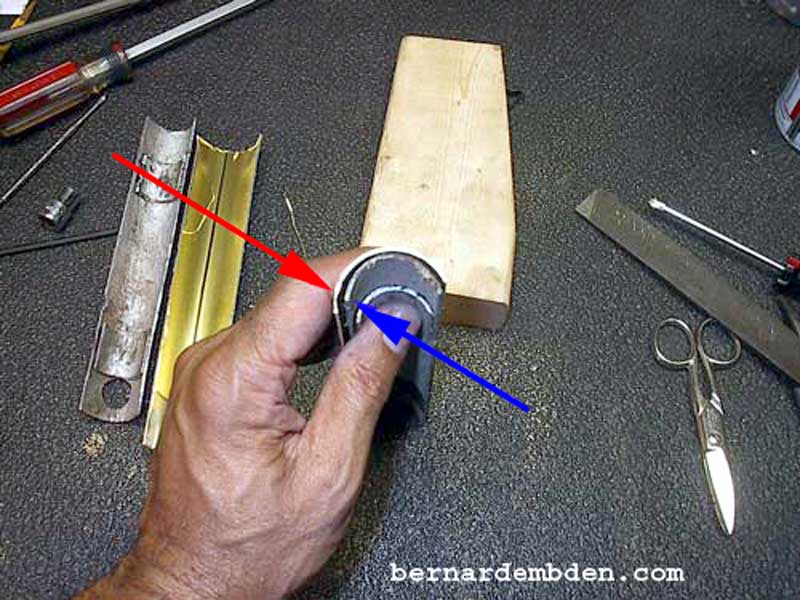

When complete I had two identical halves. Pictured below are the completed copper halves (red arrows) and the cooler insulators (blue arrows)

Initial fitting indicated that the copper jacket (red arrows) was slightly longer and wider than the fuel cooler insulator (blue arrows). In order for this project to work the copper jacket must fit the insulator like a glove.

Using tin snips I removed the excess metal from the copper jacket. Take your time with this cut. If necessary use a flat file to get the edges perfectly straight.

The copper jacket must be bent to conform exactly to the insulator. Masking tape on the jacket protects the edges while it's in the vice.

Work at it until the finished product looks like the picture below.

Using the insulator as a template mark the location of the hole the fuel lines go through.

Drill a pilot hole. Enlarge with a round file until it matches the insulator exactly. (photographs below)

Repeat the process for the other half. Picture below are the two identical completed jackets.

The cooler with the chrome jacket attached will be slightly larger in diameter. Modify the cooler brackets by drilling the mounting holes one drill size larger.

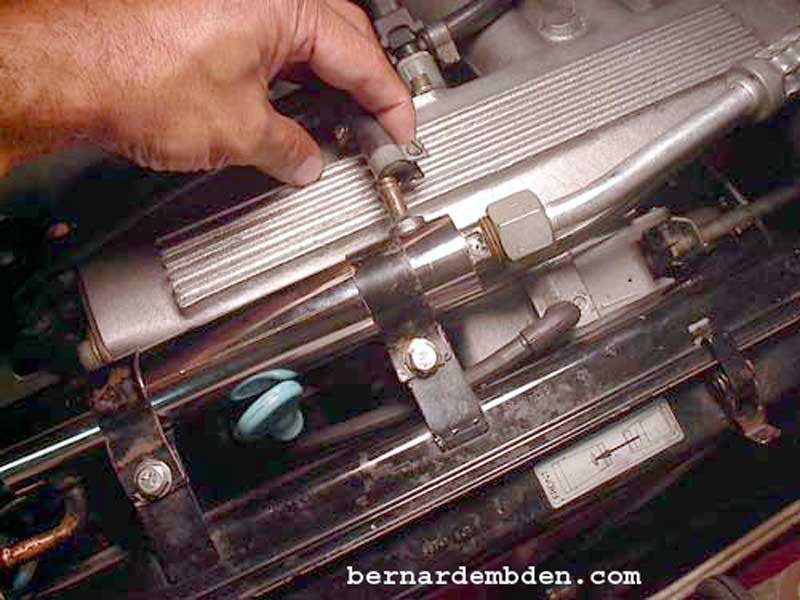

Align the chrome jackets to the insulators and install through the fuel nipples. (Photographs below)

Offer the brackets over the cooler assembly. Install mounting bolts and nuts. Re-attach fuel hoses.

Project Complete.

This low cost solution now allows the fuel cooler to look as good as the rest of the engine.